Full Automatic Carton Plant Design Solution

ยี่ห้อ :Newkuani

แหล่งที่มาของผลิตภัณฑ์ :Jiangsu,China

เวลาการส่งมอบ :20days

ความสามารถในการจัดหา :100sets/month

NewKuani MES function description-2

Accessories delivery

The ink room is based on the production schedule of the printing press. The warehouse staff scans the QR code of the ink cart in the factory MES system, enters the destination of the ink cart, and then prepares the ink into the ink cart, and the ink information is also entered into the factory MES system ; When the ink is pushed to the ink in and out position manually, the scanner of the cardboard logistics MES system scans the QR code of the ink trolley, and the logistics system automatically transports the ink to the corresponding printing machine. The conveying of the printing plate is the same process.

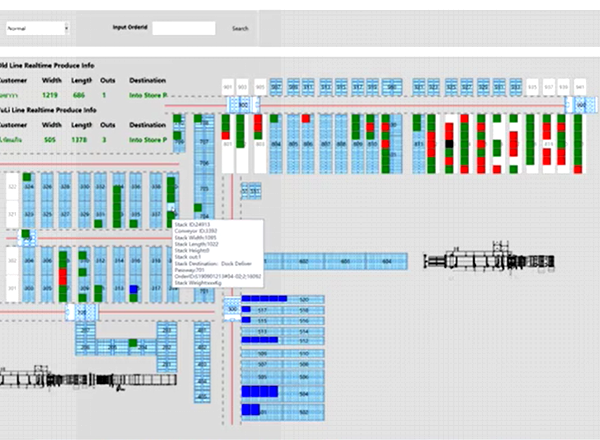

Cardboard conveyor system MES operation simulation

The operation simulation of cardboard logistics MES system is to simulate the real cardboard logistics of the factory in the computer. It can monitor the real-time operation of all cardboard and equipment usage; check the cardboard storage location, information, orders, and quantity on all conveyor belts, and timely Provide the capacity of the entire warehouse to achieve early capacity warning; Newkuani can provide remote diagnosis and remote system upgrade functions.